Pogo pins, often overlooked yet crucial in electronic connections, play a vital role in various applications. These spring-loaded connectors ensure reliable and efficient electrical contact in devices ranging from smartphones to complex testing equipment. Understanding the different types of pogo pins is essential for anyone involved in electronics design or manufacturing. With advancements in technology, pogo pins have evolved to meet diverse needs. They come in various shapes and sizes, each designed for specific functions and environments. From standard to custom configurations, knowing the distinctions can help engineers select the right type for their projects. This article delves into the various types of pogo pins available today, highlighting their unique features and ideal applications.

Overview of Pogo Pins

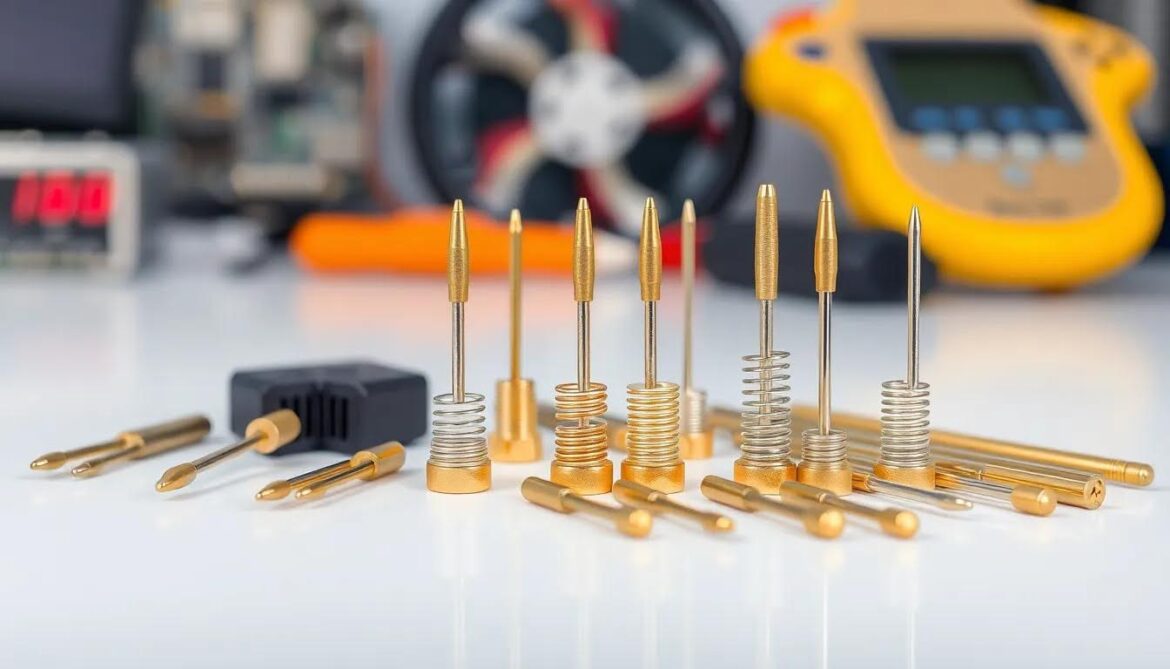

Pogo pins, also known as spring-loaded connectors, serve crucial roles in electronic devices and testing equipment. These components feature a spring mechanism that allows for reliable electrical contact in applications requiring repeated connections and disconnections. Different types of pogo pins exist to meet specific industry requirements.-

- Standard Pogo Pins : Commonly used in consumer electronics and automotive applications, these pins provide robust connectivity.

-

- High-Temperature Pogo Pins : Designed for environments with elevated temperatures, these pins maintain performance without degradation.

-

- Low-Profile Pogo Pins : Ideal for compact designs, low-profile options reduce overall device height while ensuring effective connections.

-

- Custom Pogo Pins : Tailored to fit unique specifications, custom options allow manufacturers flexibility for specialized projects.

Promax in China specializes in produ cing high-quality pogo pins that cater to various industries like aerospace and medical technology. Their manufacturing capabilities include precision engineering processes that ensure consistent quality and reliability across all connector types. Promax’s commitment to innovation means they continuously adapt their offerings based on market demands and technological advancements, making them a trusted partner for electronic component solutions.

Promax in China specializes in produ cing high-quality pogo pins that cater to various industries like aerospace and medical technology. Their manufacturing capabilities include precision engineering processes that ensure consistent quality and reliability across all connector types. Promax’s commitment to innovation means they continuously adapt their offerings based on market demands and technological advancements, making them a trusted partner for electronic component solutions.

Types of Pogo Pins

Pogo pins come in multiple types, each designed for specific applications and requirements. Understanding these types aids in selecting the right connector for any electronic project.Standard Pogo Pins

Standard pogo pins feature a basic design with a spring mechanism that allows for reliable contact. They provide excellent electrical connectivity and are widely used in testing equipment, circuit boards, and consumer electronics. Available in different sizes and lengths, including compact options like micro pogo pins , standard pogo pins can accommodate various spacing needs. Promax manufactures high-quality standard pogo pins that meet stringent industry standards, ensuring durability and performance.Spring Loaded Pogo Pins

Spring loaded pogo pins offer enhanced flexibility compared to standard options. These connectors maintain consistent pressure against surfaces during connection, which improves reliability in dynamic environments. Commonly utilized in automotive applications, medical devices, and industrial equipment, spring loaded pogo pins excel at handling more rigorous conditions. Promax’s precision engineering ensures these components perform effectively under diverse operational demands while maintaining quality across production batches.Custom Pogo Pins

Custom pogo pins cater to unique specifications required by specific projects or industries. Whether adjustments are needed for size, shape, or functionality, custom solutions allow designers to create optimal connections tailored to their products’ demands. Industries such as aerospace and telecommunications frequently benefit from these specialized connectors due to their specific performance criteria. Promax collaborates closely with clients to develop custom pogo pin solutions that align perfectly with engineering requirements while upholding high manufacturing standards.Applications of Pogo Pins

Pogo pins serve critical functions across multiple industries, ensuring reliable electrical connections in various applications.Electronics Industry

Pogo pins are essential in the electronics industry, providing reliable connections for testing equipment, smartphones, and wearables. Their spring-loaded design allows for consistent contact even with device movement or vibration. Standard pogo pins often feature gold plating to improve conductivity and prevent corrosion. Companies like Promax produce high-quality pogo pins tailored to meet specific standards required by electronic manufacturers. These connectors ensure efficient assembly processes and optimize device performance.Automotive Applications

In automotive applications, pogo pins facilitate connections within diagnostic tools and infotainment systems. Their durability withstands harsh environments while maintaining optimal functionality during vehicle operation. Spring-loaded pogo pins adapt to vibrations from road conditions, ensuring continuous electrical contact in devices such as onboard diagnostics and sensor modules. Manufacturers like Promax focus on creating robust pogo pin solutions that meet stringent automotive specifications for safety and reliability.Medical Devices

Medical devices utilize pogo pins for their precision in connecting components like sensors and monitoring equipment. The reliability of these connectors is crucial in life-saving applications where accurate data transmission matters. High-temperature pogo pins cater to sterilization processes without compromising performance or safety standards. Promax specializes in producing medical-grade pogo pins that comply with regulatory requirements, ensuring they contribute effectively to the advancement of medical technology while maintaining strict quality control measures.Conclusion

Pogo pins are vital components that improve the reliability of electronic connections across various industries. Their diverse types cater to specific needs, ensuring optimal performance in applications ranging from consumer electronics to medical devices. With advancements in technology, companies like Promax continue to innovate and provide high-quality pogo pins tailored for industry demands. These connectors not only facilitate essential electrical contacts but also adapt to challenging environments, reinforcing their significance in modern technology. Understanding the different types of pogo pins empowers designers and engineers to make informed choices for their projects.

With advancements in technology, companies like Promax continue to innovate and provide high-quality pogo pins tailored for industry demands. These connectors not only facilitate essential electrical contacts but also adapt to challenging environments, reinforcing their significance in modern technology. Understanding the different types of pogo pins empowers designers and engineers to make informed choices for their projects.